How to Repair a Cast Iron Sewer Pipe: A Complete Step-by-Step Guide

When it comes to plumbing systems, cast iron pipes have served homes for well over a century. But even the most stalwart materials face the inevitable march of time. Cracks, leaks, and corrosion can plague these pipes, leading to frustrating sewage backups and potential health hazards.

Before you resign yourself to a plumbing overhaul, consider a cast iron pipe repair. Depending on the severity of the damage, you might be able to tackle this project yourself with the right know-how. So, let’s learn how to repair a cast iron sewer pipe in this step-by-step guide.

Is a Cast Iron Pipe Repair Right For You?

The first step is assessing the damage. Cast iron pipes are susceptible to various issues:

Pinhole leaks: These tiny perforations cause slow, persistent leaks that can damage your foundation or create musty odors.

Cracks: These occur due to pressure or settling and can lead to larger leaks or even complete pipe failure.

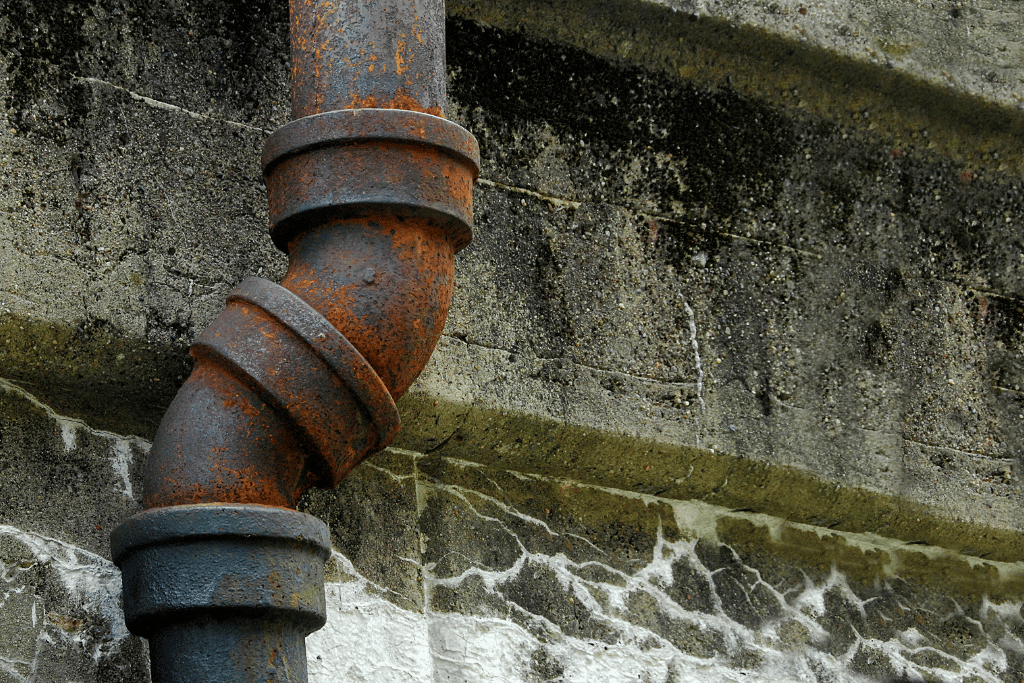

Corrosion: Over time, the inner pipe wall can deteriorate, reducing flow and increasing the risk of leaks.

DIY vs. Calling in the Professionals: What You Should Do?

For minor leaks or cracks, a DIY cast iron pipe repair might be feasible. However, for extensive damage, multiple leaks, or if the pipes are completely blocked, contacting a licensed plumber is the safest and most efficient course of action. If you’re based in Miami, and want experts to handle your plumbing projects – then get in touch with JMK Plumbing.

When to Call a Plumber:

- Large leaks or complete pipe failure: Don’t attempt to fix a major leak yourself. Shut off the water supply and call a plumber immediately to prevent further damage.

- Underground pipes: Accessing buried pipes requires excavation expertise. Leave this to a professional plumber.

- Sewer line repairs: Sewer line repairs carry a higher risk of hazardous waste exposure. Let a plumber handle it.

Signs of Cast Iron Pipes Wearing Out

Cast iron pipes were once a popular plumbing choice, but their lifespan is limited.

Rusty Water: Discolored water is a telltale sign of corrosion inside the pipes. Watch for reddish-brown water coming out of your faucets, especially when you fill a large container.

Slow Drainage: Clogged drains can be caused by various factors, but if you experience slow drainage consistently throughout your house, it could indicate rust buildup or mineral deposits restricting the flow in aging cast iron pipes.

Leaks: Cracks or holes in the pipes due to corrosion will obviously lead to leaks. Keep an eye out for damp spots around pipes or fixtures, and listen for dripping or trickling sounds.

Sewer Backups: In the worst-case scenario, weakened pipes can lead to sewage backups, where wastewater overflows from drains or toilets. This is a serious health hazard and requires immediate attention from a plumber.

Tools and Materials You’ll Need For Cast Iron Pipe Repair

If you’ve determined a DIY cast iron pipe repair is the way to go, assemble your tools and materials:

- Safety gear: Safety glasses, gloves, and a respirator are essential.

- Work rags and a bucket: For cleaning and collecting debris.

- Wire brush and sandpaper: To prepare the pipe surface for patching.

- Leak sealant/epoxy putty: Choose a product specifically designed for cast iron pipes.

- Clamps and waterproof tape (optional): For larger cracks or holes.

- Pipe cutters and wrenches (for replacement sections): Needed if replacing damaged pipe sections.

Step-by-Step Guide to Cast Iron Pipe Repair: Detailed Breakdown

Preparation is Important:

- Turn off the water supply: Locate the shut-off valve for the affected area. It might be located beneath the sink you use most often, near the washing machine hookup, or even outside near the property line. Completely turn the valve clockwise until it stops. Double-check by opening the furthest faucet on the affected line and ensuring no water flows.

- Clear the work area: Remove any cabinets, shelving, or Gegenstände (German for “objects”) that might hinder access to the pipe. You’ll need enough space to work comfortably and safely.

- Identify the damage: Carefully examine the pipe for leaks, cracks, or corrosion. Look for weeping water stains, visible cracks, or areas that feel soft or uneven. A flashlight can be helpful to illuminate shadowed areas.

- Isolate the damaged section: If possible, shut off valves to isolate the damaged section of pipe. This will minimize the amount of water that needs to be drained and make the repair process easier.

- Drain the pipes: Depending on the location of the damage, you might need to drain the entire system or just the affected section. Open the lowest faucet on the line (basement floor drain or exterior cleanout) and any other faucets above the repair area to allow water to drain completely. Place a bucket under the open faucet to collect any dripping water.

Patching a Leak or Small Crack:

- Prepare the repair area: Use a wire brush to remove any dirt, rust, or debris from the pipe surface around the damage. Scrub thoroughly to create a clean and slightly roughened surface for better adhesion of the patching material.

- Dry the area completely: Use clean rags to remove any moisture from the work area. Moisture can prevent the patching material from adhering properly.

- Apply leak sealant or epoxy putty: Follow the manufacturer’s instructions for mixing and application. Typically, a two-part epoxy will require mixing equal parts of resin and hardener. Mix thoroughly on a clean surface and apply generously to the damaged area, covering any cracks or holes completely.

- Smoothing and shaping: Use a putty knife or gloved finger to smooth the patching material over the repair area. Ensure there are no gaps or uneven surfaces. Wetting your finger slightly can help smooth the epoxy.

- Setting time: Allow the epoxy to cure completely according to the manufacturer’s instructions. Curing times can vary depending on the product, so be sure to factor this in when planning your repair.

- Optional reinforcement for larger cracks: For cracks larger than ¼ inch, consider using waterproof tape or a mesh patch in combination with the epoxy for added reinforcement. Apply the tape or mesh patch over the epoxy while it’s still wet, pressing it firmly to ensure good adhesion. Then, apply another layer of epoxy over the tape or mesh to create a watertight seal.

Replacing a Damaged Pipe Section (experienced DIYers only):

- Cutting out the damaged section: Use pipe cutters specifically designed for cast iron to carefully cut out the damaged section of pipe. Make clean, straight cuts to ensure a good fit for the replacement pipe.

- Measuring and cutting replacement pipe: Measure the exact length of the removed pipe section. Cut a replacement pipe section from PVC or another approved material to match the exact length. Ensure a snug fit, but avoid forcing the pipes together.

- Deburring the pipe ends: Use a file or sandpaper to remove any sharp edges or burrs from the cut ends of both the replacement pipe and the existing pipes. This will help create a smoother connection and prevent leaks.

- Assembling the joint: Apply a thin layer of pipe dope or approved thread sealant to the male threads of the replacement pipe and the existing pipe. Carefully screw the replacement pipe section into the female threads of the existing pipe, turning by hand until snug.

- Tightening the joint: Use wrenches to tighten the joint further, but be cautious not to over-tighten and crack the cast iron. Tighten firmly until snug and leak-free. Some joints may use clamps instead of threads. Tighten the clamps securely using a screwdriver or wrench.

Testing and Finishing Up:

- Turn on the water supply slowly: Slowly open the shut-off valve that controls the water supply to the repaired area. Monitor the repair site closely for any leaks.

- Leak check: Once the water supply is on, inspect the repair site for any leaks. Look for dripping water or signs of dampness around the repair area. Also, run water through the faucets or drains connected to the repaired section for several minutes. Listen for any hissing sounds that might indicate leaks.

- Tightening adjustments (if necessary): If you detect leaks, carefully tighten the clamps or fittings around the repair area. Do this gradually and avoid over-tightening. If leaks persist, shut off the water supply and re-evaluate your repair technique. Consider consulting a professional plumber at this point.

- Clean Up: Once the repair is complete and leak-free, clean up the work area. Dispose of used rags, gloves, and other materials properly. Wash your hands thoroughly with soap and water.

Safety Precautions:

- Always wear safety glasses and gloves to protect your eyes and hands from dust, debris, and sharp edges.

- Use a respirator when working with cast iron pipes, as dust and particles can be harmful if inhaled.

- Be mindful of lead exposure: If your home was built before 1978, there’s a chance the pipes contain lead. Lead is a serious health hazard, and disturbing lead pipes can release lead dust and particles. If you suspect lead pipes, consult a professional plumber with lead abatement experience.

- Work in a well-ventilated area: Open windows and doors to ensure proper air circulation and avoid fume buildup.

Additional Tips:

- Take pictures of the pipe layout before you disassemble anything. This will be helpful for reassembling the pipes correctly.

- When using epoxy putty, work in small batches, especially if you’re new to using it. Epoxy cures quickly, and you don’t want to waste any.

- If you’re unsure about any step in the process, err on the side of caution and consult a professional plumber.

Final Words

And that’s the complete process on How to Repair a Cast Iron Sewer Pipe. While patching small leaks or cracks with epoxy might seem like a quick fix, for the most reliable and long-lasting repairs, especially for larger holes or damaged sections, consider calling a professional plumber like JMK Plumbing.

We have the experience and tools to assess the damage and recommend the best course of action, whether it’s a sectional replacement, trenchless sewer repair, or complete sewer line replacement – we can handle it all.